Ball Mill Process. It is necessary for ... The ball mill can be used in the processing of wet or dry materials, as well as contaminated or safe chemical materials.

A dry process airswept ball mill. Typical roller mill layout. ... Types of dry rawmill include ball mills, roller mills and hammer mills. Ball mills

Dry Ball Mill. Type : Mill Equipment Capacity : /h. Application field : Dry process ball mill is widely used in powdermaking production line including ...

Dry ball mill can work without adding water, which is the key point to distinguish dry and wet ball mill. Dry ball mill is a straight cylinder, which is provided with ...

· and the heat generation in the process of dry grinding . In wet Grinding process, ... This should apply to ball mill grinding as well as autogenous grinding.

Ball mill is a key device to crush materials after being broken. It is widely used in cement, silicate products, new building materials, refractory, fertilizer, non ...

A ball mill can grind and homogenize small sample volumes down to the nano range. The Emax is an entirely new type of ball mill for high energy input.

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

ball mill process – Coal processing system Machine for sale. Find the Right and the Top ball mill process for your coal handling plant! liming, a mining machines ...

wet and dry process ball mill manufacturerYantai Xinhai . Ashoka is one the leading Ball Mills Manufacturers In India, the ball mill is a horizontal includes wet ...

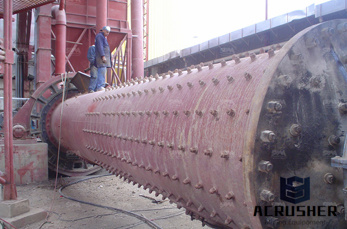

Ball mill is the key equipment for recrushing the materials after they are primarily crushed. Ball mill is widely used for the dry type or wet type grinding of all ...

GSM dry process ball mill GSM stirred type grinding machine has the unique patented design concept. It contains a brand new internal structure of the grinding cylinder, ...

Ball Milling Process Introduction: The ball mill is the key milling machine to break and to smash materials. It also is an effective tool for many materials ground ...

· Ball mill is used to grinding ores or other materials after crusher, it is the mechanical equipment for getting finer particle products.

STUDY OF BREAKAGE CURVES IN ULTRAFINE BALL MILL DRY GRINDING P. Hari Babu1, R. Bhanu Prasad2 ... breakage process were first order and measured the .

Dry Ball Milling Process Of Powder. milling of metal powder process vitalestate. ... Ball Milling Process Introduction: The ball mill is dry or wet grinding.

dry process ball mill. Improved Jc of MgB2 superconductor by ball milling using different . In this paper, the effects of ball milling B powders using different media ...

ball mill dry process diagram; Dry Process Vs Wet Process Of Cement Mill. The difference between wet and dry process of cement manufacture is .

Hosokawa Alpine. As a leading ... Powders of extremely high fineness can be produced with ball mills and agitated media ... Different mill designs make both dry or ...

Talk with the Experts at Paul O. Abbe about your process requirements and Ball Mill Loading, Wet Milling, Size Reduction needs.

Ball MillBall Mill Shanghai Shibang Machinery Co., Ltd. ... dry process and wet process. Ball Mill is crucial equipment for grinding after materials are crushed.

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index ...

Grinding in Ball Mills: Modeling and Process Control ... The design of a ball mill can vary significantly ... The grinding process can also take place in dry or wet ...

A dry process will be preferred. ... Ball mill . 1500x5700. 1. 90. ... Manganese ore wet and dry separation process flow

WhatsApp)

WhatsApp)