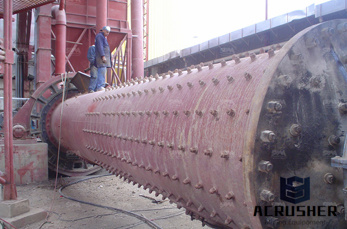

Ball mill,Ball mills,Ball mill machines Machinery. Ball mill is the key equipment for grinding after, such as cement, silicate, new, there are dry ball mills and ...

... (the "critical speed") ... These have been used for many years for the less exacting raw ... The cement mills on a cement plant are usually sized for a ...

THE GRINDING CHARGE OF ROTARY MILLS ... industry, the raw used to produce cement ... ncr = critical speed of this, when grinding

Raw mills usually operate at 7274% critical speed and cement mills at 7476%. Calculation of ... of a threecompartment mill for dry grinding of cement raw ...

Critical Speed For Ball Mill; ... Calculation of balance in cement grinding. raw grinding mill cement industry pdf « Top Blog Formula Support ... cement mills mass.

Power Transmission Products Solutions for Cement Processing ... cement mills for more than a century. ... such as moving raw

Ball mills are cylindrical or conical shell ... energy input is required in separate grinding of ceramic raw materials than ... The critical speed is calculated as ...

In the cement industry, the dry process is always used except some old installations where the raw mills ... between 70 and 75% of the critical speed.

The grinding works on the principle of critical speed. ... lines for powders such as cement ... ball mills there is a second type of ball mill called a ...

Nov 16, 2011· Video embedded· Process in vertical raw ... mill for raw and cement grinding Duration: 2:47. FLSmidth 3,029 views. 2:47. Ball Mill Critical Speed Working ...

Bulk Handling Industry. ... Cement mills, power plants, ... The most critical applications are in the cement industry.

types of raw mill charge ratio in cement pdf ... (.pdf Grinding Ball Charge in Mills Mill Charging Total ... to calculate critical speed of ball ...

The ideal mill speed is usually somewhere between 55% to 75% of critical speed. Critical Mill Speed. Critical Speed ... ABBE Jar Rolling Mills are designed to support ...

The analysis of size reduction in tumbling ball mills using the concepts ... the condition 70% of critical speed of cement ball ... To Ball Mill Critical Speed.

ing most moist raw materials for the production of cement clinker. The flexible ATOX™ raw mill can prepare ... For normal raw mills

raw mill, coal mill and cement mill. ... reason was a demand for increased ventilation of cement mills. ... is more than the critical speed and the centrifugal ...

Portland cement is the ... in a cement kiln, a mixture of raw ... An independent research effort of AEA Technology to identify critical issues for the cement ...

A raw material grinding circuit ... Lynch et al. and Benzer et al. developed a modeling approach for the two compartment cement mills using ... critical speed and ...

OPERATIONAL EXPERIENCE FROM THE UNITED STATES'' ... utilized Vertical Roller Mills (VRM) for grinding of raw materials ... and cement raw materials are ...

A cement mill (or finish mill in ... (the "critical speed") ... The cement mills on a cement plant are usually sized for a clinker consumption considerably greater ...

Expert system for optimization of cement mills ... Vertical Roller Mill in Cement Raw Mix USM Research and raw mix grinding ... critical rotational speed nc of ...

... raw mill, ball mill etc ... » critical speed of cement ball mill. ... cement plant ball mills critical speed formulae. critical speed of cement ball mill, ...

3 Chambers mills are used in the cement section ... These kinds of mills are used in the raw meal section of a ... the critical speed is defined as the ...

Mar 08, 2013· Selecting and using raw materials for cement ... CALCULATION OF BALL MILL GRINDING EFFICIENCY. ... step step by procedure on how to work out on cement ball mills to.

WhatsApp)

WhatsApp)