Milling and Grinding Ball mills: ... tungsten carbide or PTFE. You are able to ensure an outstanding grinding process and avoid contamination of your sample.

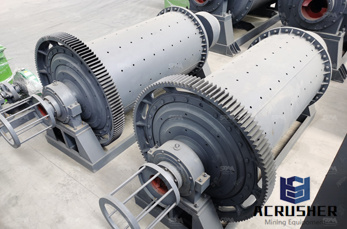

What is a Ball Mill? A ball mill is a type of grinding mill, purposed similarly to the sag mill or other mining crushers. These machines are used to grind or mix ...

Basics of Grinding Fundamental Manufacturing Processes Video Series Study Guide 2 Another aspect of grinding wheels is their pore structure or density, which

Jig Grinding, EDM or HighSpeed Milling? When evaluating new processes for mold manufacture, ... With the realization that jig grinding was a necessary process, ...

GRINDING MACHINES Grinding is the process of removing metal by the application ... Milling and Grinding Lathe Attachment Also called a VersaMil this attachment is a ...

Grinding Roughs Out a New Niche Tyrolit Advocates a Patented Grinding Process for Rough and Finish Machining of Aerospace Parts. In the past, grinding has been a ...

A Model Camshaft Grinding Process. Optimizing a camshaft lobe grinding cycle has traditionally been based less on science and more on educated guesswork and .

Milling Grinding Flaking Buhler Group. Milling Grinding Flaking Every detail counts. The roller mill is by far the most important grinding machine in a mill.

A sixweek course designed to take students through the complete cycle of raw material grinding and preparation, clinker grinding, milling and separation cycles.

The Milling Process. The milling process has evolved from the days of grinding the wheat between two large stone wheels (although this process does still occur in a ...

Grinding process. Grinding is defined as machining with geometrically undefined cutting edges. Advantages of grinding over other machining methods:

Milling, Grinding Flaking Every detail counts. The roller mill is by far the most important grinding machine in a mill. Whether processing maize, wheat, durum wheat ...

Milling, Grinding Flaking Milling, Grinding Flaking Every detail counts. The roller mill is by far the most important grinding machine in a mill.

,milling,milling,milling,milling,milling,milling。

Gold Ore Grinding Mill for Milling Process. In applying MPC algorithm to ball mill grinding process, such as the, it is necessary to properly select the values of ...

Particle size technology for integration in milling and grinding solutions and for automating control.

Effective grinding and milling of metal ores is essential in liberating and recovering valuable minerals. Energy consumed in the comminution process is a major cost ...

BSM4 : WORKSHOP PROCESSES 1. MILLING ... Gear finishing process ( Gear sharing burnishing, grinding honing ... Milling is a machining operation in which a workpart ...

Grinding, Milling and Turning; Coating and Electroplating; ... CNC Surface Grinding. We use a lowforce process to grind a variety of materials for flatness, ...

As a material removal process, machining is inherently not the most economical choice for a primary manufacturing process. Material, which has been paid ...

Expanding capacity matters to grinding and milling ... you need to go to in order to ensure that every step of the machining process is as efficient and ...

Cement grinding process,Vertical roller mills and ball mills . Around 110 years ago a Danish engineer, M. Davidsen, patented a pioneering invention in France which ...

Ultrasonic WetMilling and MicroGrinding. Ultrasonication is an efficient means for the wetmilling and microgrinding of particles. Besides dispersing and ...

Media Advances Milling The most efficient fine grinding takes place when both impact action and shearing force are present. by Robert Schilling, National

WhatsApp)

WhatsApp)