Froth flotation grinding mills,Copper ore ball mill process One Response to Froth flotation grinding mill January 13th, Mining Equipment and Supplier News.

Introduction to Mineral Processing. ... froth flotation entails crushing and grinding the ore ... the pulp to reduce the flotation of the copper minerals while ...

Crushing, Grinding and Flotation Improvements ... A copper and molybdenum (moly) flotation concentrator to treat 25,000 tons per day was designed in .

Investigation of Flotation Parameters for Copper Recovery from Enargite and Chalcopyrite Mixed Ore ... minerals requiring finer grind.

openUP (July 2007) Effects of grinding environment on the flotation of Rosh Pinah complex Pb/Zn ore Y. Weia and Sandenber...

Effect of Grinding Environment on Galena Flotation The Open Mineral Processing Journal, 2015, Volume 8 3 DMP [24]. One millilitre each of DMP, copper (II) sulphate,

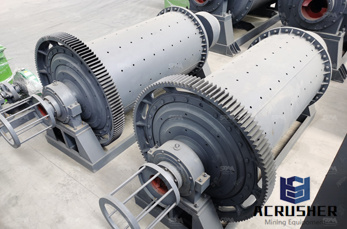

Froth flotation grinding mills,Copper ore ball mill process Gold ... Froth flotation was the key process in extracting the valuable minerals from the ... mounted ...

Flotation 1 Fundamentals is the first of a suite of three courses on flotation theory and practice from ... for training crushing, grinding and flotation ...

60 Centuries of Copper: The Flotation Process. ... The powdered product of grinding the ore is fed into a series of tanks called flotation cells which are ...

2200 TPD Crushing, Grinding, Flotation, Filtration, Copper, Zinc Concentrate Plant. Major Equipment Includes: Jaw Crusher AC: 36 x 48; Larox Filter Press PF32/38 ...

Introduction to Mineral Processing. The process of froth flotation entails crushing and grinding the ore to a fine size. ... They are used to improve the selectivity ...

FLOTATION CHARACTERISTICS OF A COMPLEX COPPER ORE: A COMPARISON BETWEEN WET AND DRY GRINDING . collected at 2, 4 and 8 minutes of flotation. After collection, the ...

Flotation Concentration ... The copper ore slurry from the grinding mills is mixed ... The bubbles that flow over the edge of the first set of flotation ...

Vacuum Filters (for Froth Flotation Concentrates). Download PDF Tenova. spiral concentrates or pretreats spiral feed, efficiently producing Horizontal belt vacuum ...

An underground copper ore and an open pit copper ore were crushed to a size of − mm before grinding and flotation. The mineral composition of the two ores ...

Applying OneStage Grinding and Flotation to Improving Copper Recovery of a FineGrained CuMo Sulphide Ore

grinding and flotation mills. gravity concentration of gold from base metal ... Froth flotation grinding mills,Copper ore ball mill. Froth Flotation ...

Copper smelting slags are hard materials. Therefore,to recover their copper by flotation method, grinding should be carried out to obtain optimal particle size.

Grinding Media — Its Effect on Pulp Chemistry and Flotation Behaviour — Fact or Fiction? ... copper recovery compared to grinding ... PULP CHEMISTRY AND FLOTATION ...

gypsum grinding sandstone copper extraction flotation. gypsum grinding sandstone copper extraction flotationGrid Type Ball Mill A grinding equipment with steel rod as ...

Copper Flotation Beneficiation Plant Design. Copper Flotation Beneficiation Plant Design Process Crusher, ... a 16 grit concrete grinding pad label; ...

But the plant scale flotation recoveries of copper were the same ... Keywords Conventional and autogenous grinding, flotation pulp chemistry, low grade copper ore.

Home / FAQ / Copper ore Conventional Milling/Flotation . ... After grinding, ... there are 11 copper flotation concentrators in operation in Arizona and New Mexico.

02 Mineral ... 02 MINERAL PROCESSING ... Mineral Processing MP33 NASH IN THE OPTIMIZATION OF COPPER FLOTATION ...

WhatsApp)

WhatsApp)